PEOPLE AND PARTNERSHIPS.

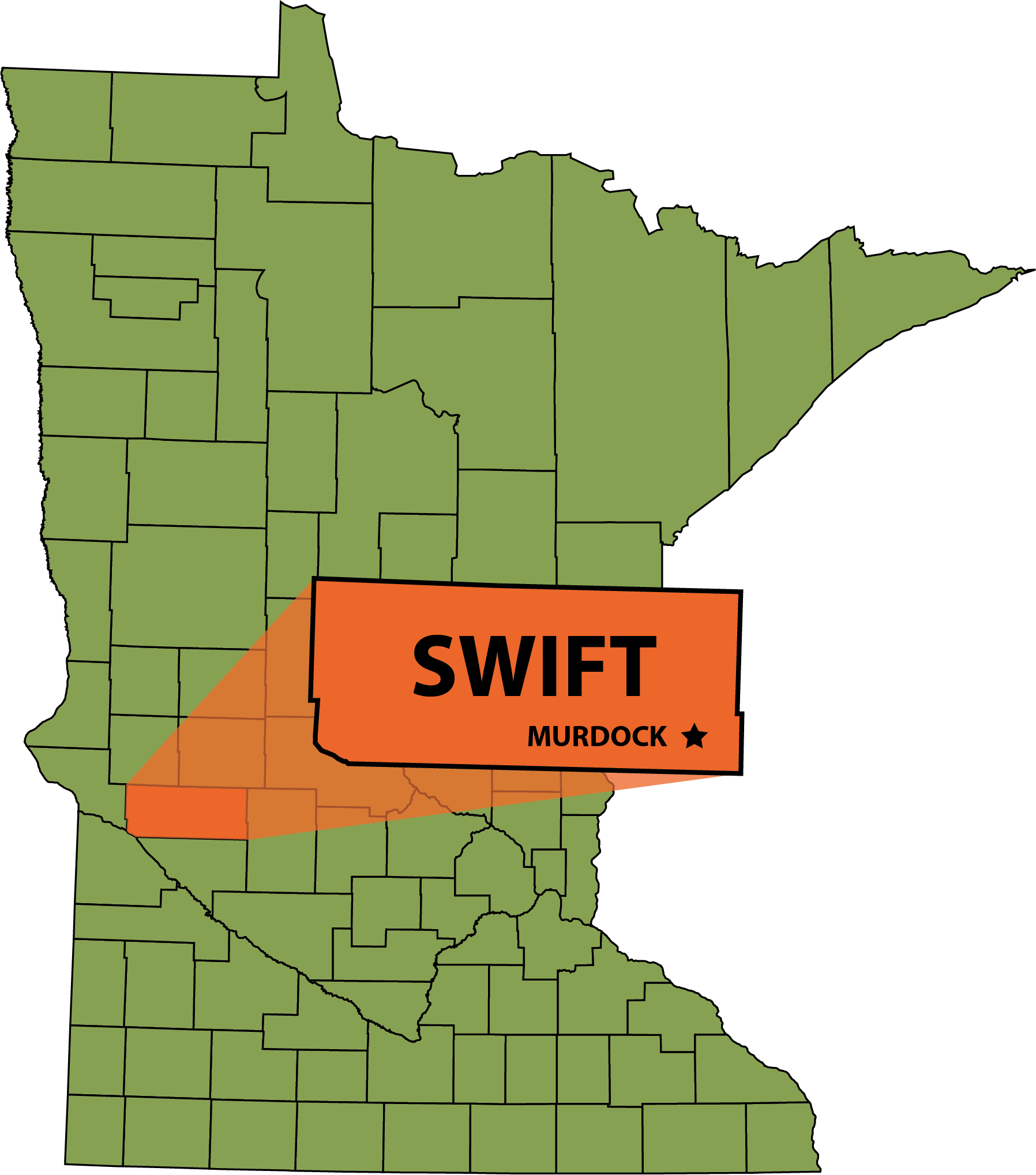

For Mike Yost, 71, of Yost Farm near Murdock, Minnesota, these are the two absolutely essential elements for continued success in his family’s operation. However, as anyone who has managed a business knows, it’s not about finding just any person, but the right one with the proper attitude.

“When I grew up, we just needed someone who could fill a size 4 hat and a size 48 shirt,” he said. “Now, we need a lot more informed and sophisticated team member than what we did in the past, someone who understands what we’re trying to do here.”

Yost Farm was established on a single quarter section nearly 150 years ago by Mike’s great-grandparents, John and Catherine, who immigrated to Minnesota from the town of Malmedy; at the time, Malmedy was part of western Germany, but the territory now lies within the borders of modern-day Belgium.

Mike grew up working on the farm and carries on the family tradition, and the farm’s core values were passed along from the founding ancestors and eventually were imparted to him by his father, Bill.

“There are two things my dad really taught me, instilled in me at an early age,” Mike said. “He said, if you’re going to be successful at farming, you need integrity and a really strong work ethic. That idea was part of me even before I went to grade school.”

As a kid, Mike would help pick rock, do the chicken chores, and feed cattle. Now, the farm is fully focused on production agriculture, raising corn, alfalfa, soybeans, dry beans, and sugar beets over thousands of acres. While the farm has grown in both acres and technology, Mike believes some things will always remain true on the farm.

“There’s been two constants – farming is still a very capital intensive, weather-dependent business,” he said. “What’s changed is the acceleration of change brought upon by technology.”

Especially in the past couple of decades, farming technology has advanced significantly, and the Yost operation continually faces the challenge of integrating and adopting new tech.

Where once, farm workers used to know how to run a scoop shovel, now they have to be able to run computers. Not only that, but as roles change with added technology and added acres, the workforce must become more educated and their skills more diversified. The Yost Farm employs over a dozen year-round employees, and they foster a team-based culture, bringing people on board that embody their values, investing heavily in those people to become better versions of themselves.

“First of all, we try to hire people that have our core values – integrity, strong work ethic, a great attitude, and the ability to adapt to change,” Mike said. “Then, we do team building on our farm and send people to leadership training. We bring in consultants and send the entire staff to tour facilities, and we regularly bring everyone together to discuss the goals of the farm.”

Introducing team members to outside ideas allows Yost Farm to continue to be adaptable on the strength of its people, and Mike lives by this example, as well. After graduating college, he didn’t immediately return to the farm, choosing instead to work as a grain trader for six years. Not long after returning to the farm in 1987, Mike helped organize his county soybean association, eventually moving up the ranks through the state and national organization, becoming the ASA national president in 1998.

Through this role, he became active on a few USDA advisory committees, and this involvement led to him joining the Bush administration as an associate admin of the farm service agency in 2003, culminating in an appointment as the administrator of the United States Foreign Agricultural Service, allowing him to travel the world discussing trade issues and granting him unique insights into the role of U.S. agriculture on the world stage.

“You really got a sense of what’s going on around the world,” Mike said. “There’s a very hungry, politically unstable world out there that we need to help feed, and I learned American agriculture is truly second to none. We have a lot of advantages other countries don’t.”

Mike led delegations to numerous locations, including China, Brazil, and Africa, but one of his standout memories includes a trip to a meeting outside of the Green Zone in Baghdad back in 2007 where he was accompanied by armed escorts. Other impactful trips included visiting a school in sub-Saharan Africa where children aged 5 through 13 subsisted on a mash of corn and soybeans cooked over an open flame and sang “God Bless America” when they finished their meal. Witnessing such extremes in global food consumption had a major impact on his perspective.

“There’s two types of people in this world. Those who eat to live – that’s the majority – and those who live to eat, like many in the Western world,” Mike said. “Those who live to eat want non-biotech products, cows they want to know the name of – stuff that doesn’t have impact on food or environmental safety. Concerns and demands of the Western consumers that want all these things because they read it on the internet causes companies to market products that have and are going to have negative and severe consequences on those who are trying to survive on a dollar or two a day. It is going to drive the cost of subsistence consumption to a place where it’s simply unaffordable.”

Yost is quick to emphasize that consumers should be able to make a choice. His main concern is that those choices be well informed with facts about safety and the impact misinformation truly has on the food market.

“I have no problem with people eating organic, that’s all fine,” Mike said. “Do it if that’s what you prefer, but don’t say there’s a negative effect from biotech. At the same time, farmers need to be more sustainable because it’s the right thing to do to try to raise more with less.”

In keeping with the philosophy of raising more with less, Yost Farm continues to adopt new technologies aimed at maximizing efficiency of all aspects of production, from inputs to equipment and labor usage. The operation constantly collects data on all of this and feeds it into Conservis, a farm management software program.|

“We really know our cost of production,” Mike said. “We can do a printout of every field, how many minutes in each pass, gallons of insecticide, fertilizer. We’re dialing in very accurately how successful products are, and which hybrids respond to things like fungicide applications better than others. We keep track of all the parts that go on the planter and how many hours we work on it, like you would at an implement.”

The Yost operation also gains efficiency through volume and the strength of its unique internal partnerships.

These partnerships allow for diversity and both horizontal and vertical integration. The farm’s website, yostfarm.com, lists more than three dozen entities and individuals that they work with or have various types of agreements with.

“We’re very successful at working partnerships,” Mike said. “A significant part of our land is in a partnership. We’ve got custom harvesting, manure pumping and dairy partnerships. All of these have been catalysts for growth and have helped us learn a lot, making us a smarter, more efficient farm. I think that’s the future in production ag because we’re in the volume business. To get to critical mass, you’re going to need to partner up with people.”

One of his longtime external partners is his chemical supplier, Hefty Seed Company out of Hancock, Minnesota. The Yosts have done business with Hefty’s for more than 20 years, and the operation relies on the knowledge and service provided by their local agronomist, Adam Gibson.

“Adam is just knowledgeable,” Mike said. “He knows what we’re trying to accomplish on our farm, knows we’re cost conscious, and knows we want to have clean fields. He knows the weed spectrums and soil types we have here. He’s been terrific – not only a good vendor, but a good source of information.”

In addition to information, Mike also appreciates the attention to detail that Hefty’s brings to the table in terms of customer service and efficiency in terms of both product cost and time spent getting what they need.

“They’ll lay out brand name vs generic, what the options are there, including some of the rebate programs,” he said. “We come to pick up the pallet, it’s there and shrink wrapped by the time we arrive. We never have to wait; it’s a five-minute pickup. Then they do things like process the rebates for us or remind us what we need to do to get the most out of rebates. Sure, these are small things, but they’re very critical to what we’re trying to accomplish.”

Although partnerships are essential for Yost Farm, Mike constantly emphasizes that the cornerstone of making it all happen comes back to the value of their people. He believes that when you have the right people, your farm can overcome any challenge.

“The quality of our team and our partnerships – these are the two major reasons we are successful,” he said. “We’ve got a great team here, and that’s our key to the success of our farm. The mentality of our farm is we want to hire great team members so we are ready for the next opportunity. And our team is second to none.”